Sensor Fusion for Sensor Calibration in Robotic Surgery

The Smart Grasper as initially conceived by Brown et al. in their 2008 paper.

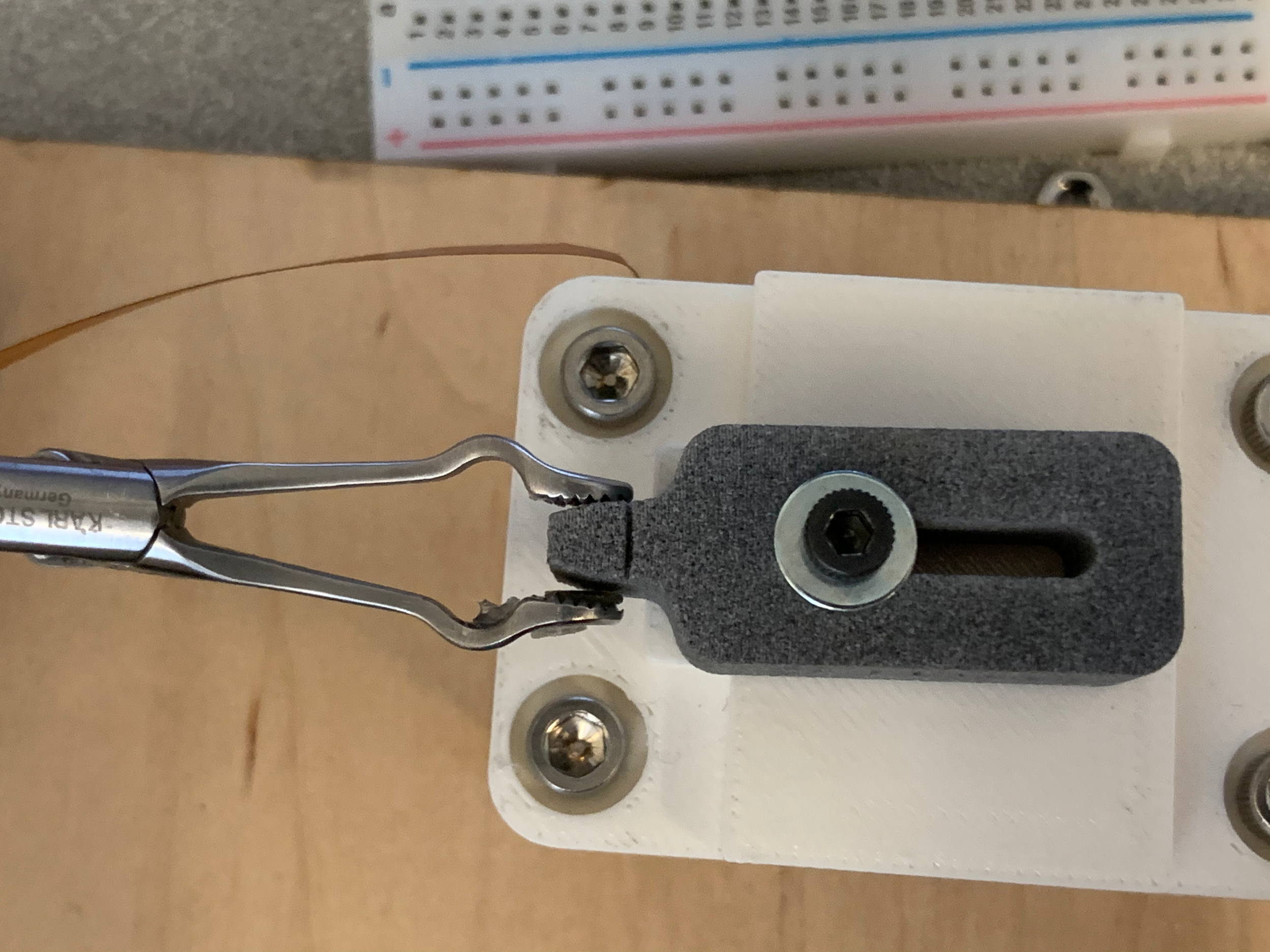

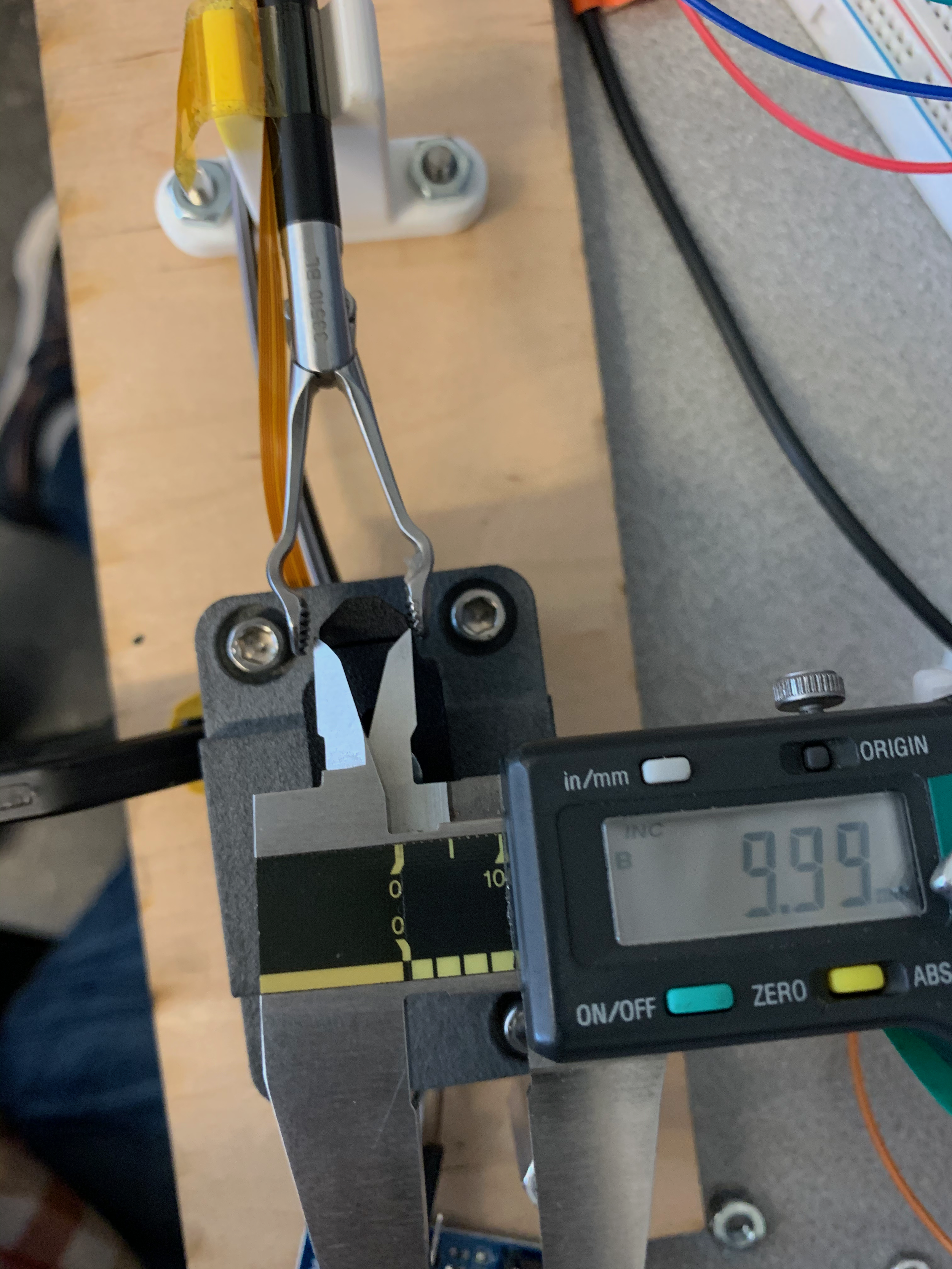

The jaw distance I was looking for corresponds to the distance between the two red dots in the picture.

I pursued research in addition my coursework during my time as a master’s student at the University of Washington. Working for Blake Hannaford in the BioRobotics Lab gave me the opportunity to explore the surgical robotics field. My research explored how to measure the force that a set of laparoscopic jaws applied to tissue and the distance between those jaws.

There are many reasons to want to know the jaw force and the jaw distance. One of the most cited use cases is providing feedback to a physician during robotic surgery. This allows the surgeon to find anomalously tough—and therefore possibly cancerous—tissue. The most immediate reason for wanting this information, however, was that it would form part of another student’s doctoral thesis.

The biggest challenge facing my research was one of resources. The project was only minimally funded, so everything had to be done as cheaply as possible. This meant reusing old hardware rather than designing a purpose-built solution.

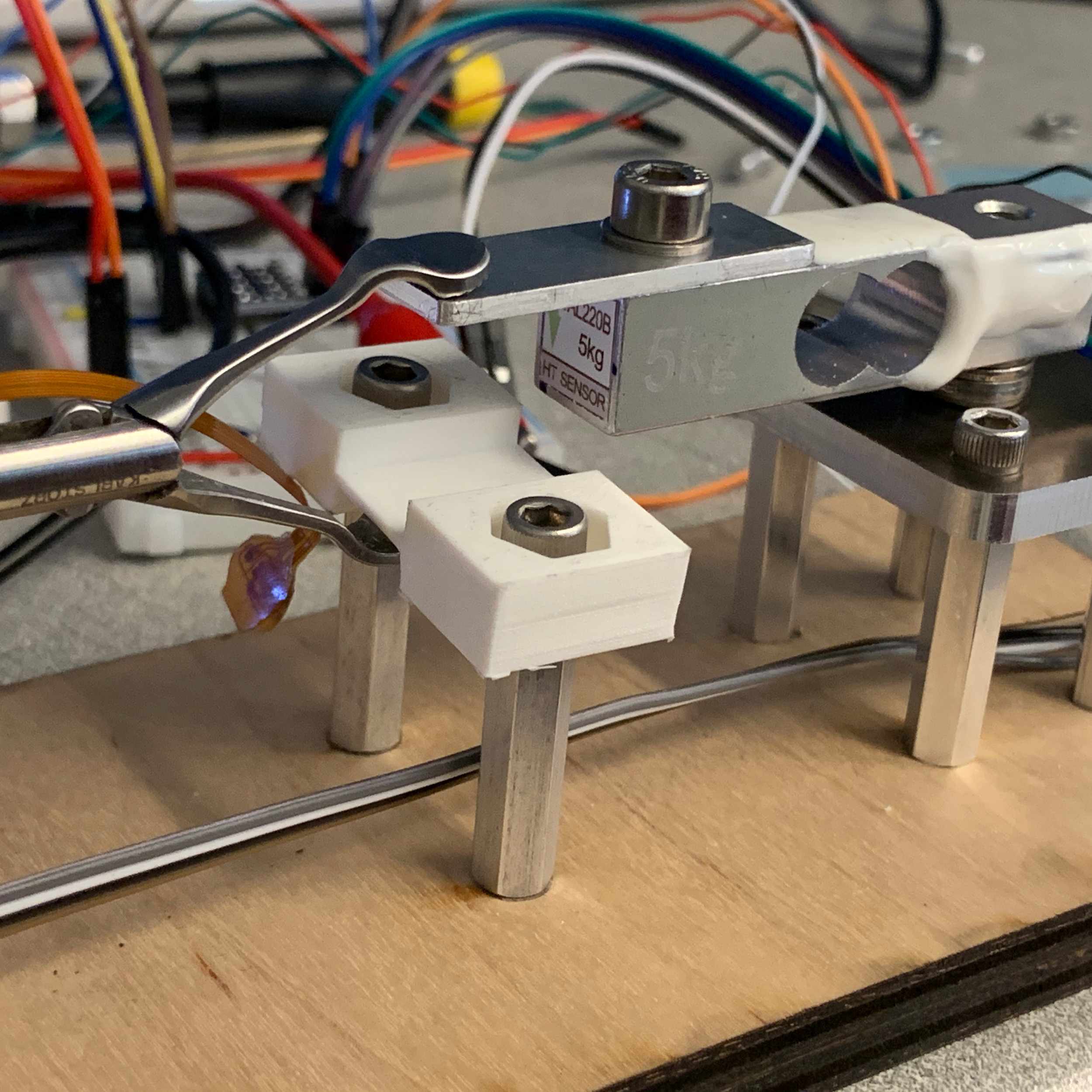

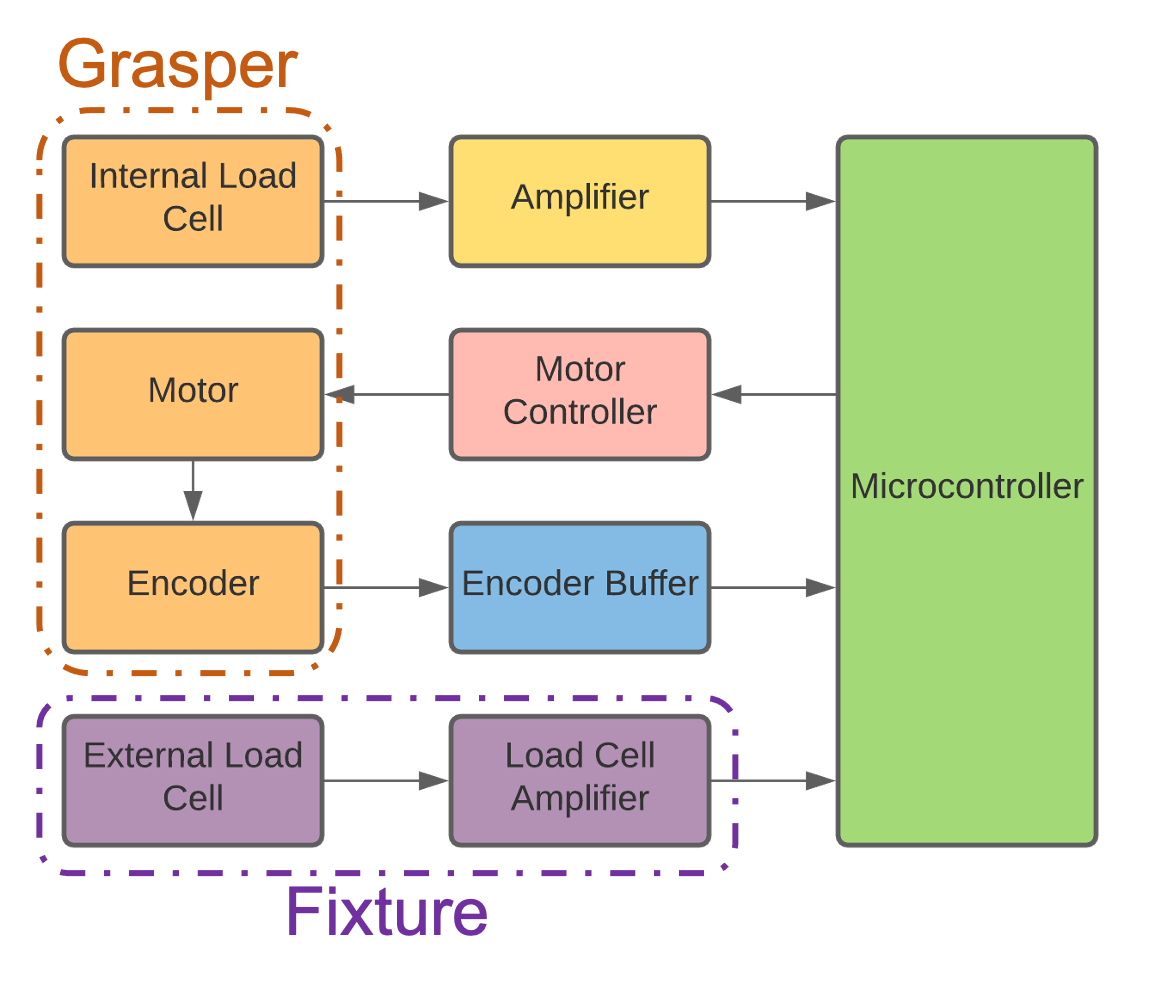

The Smart Grasper was initially developed in 2008 and has been built upon over the years. It has a motorized drive system that turns a paddle wheel using a steel rope. The paddle wheel is attached to a ball-in-socket joint that moves a pushrod back and forth, which opens and closes the jaws. There is an encoder on the motor that records its position and an internal load cell sensor that records the force on the pushrod.

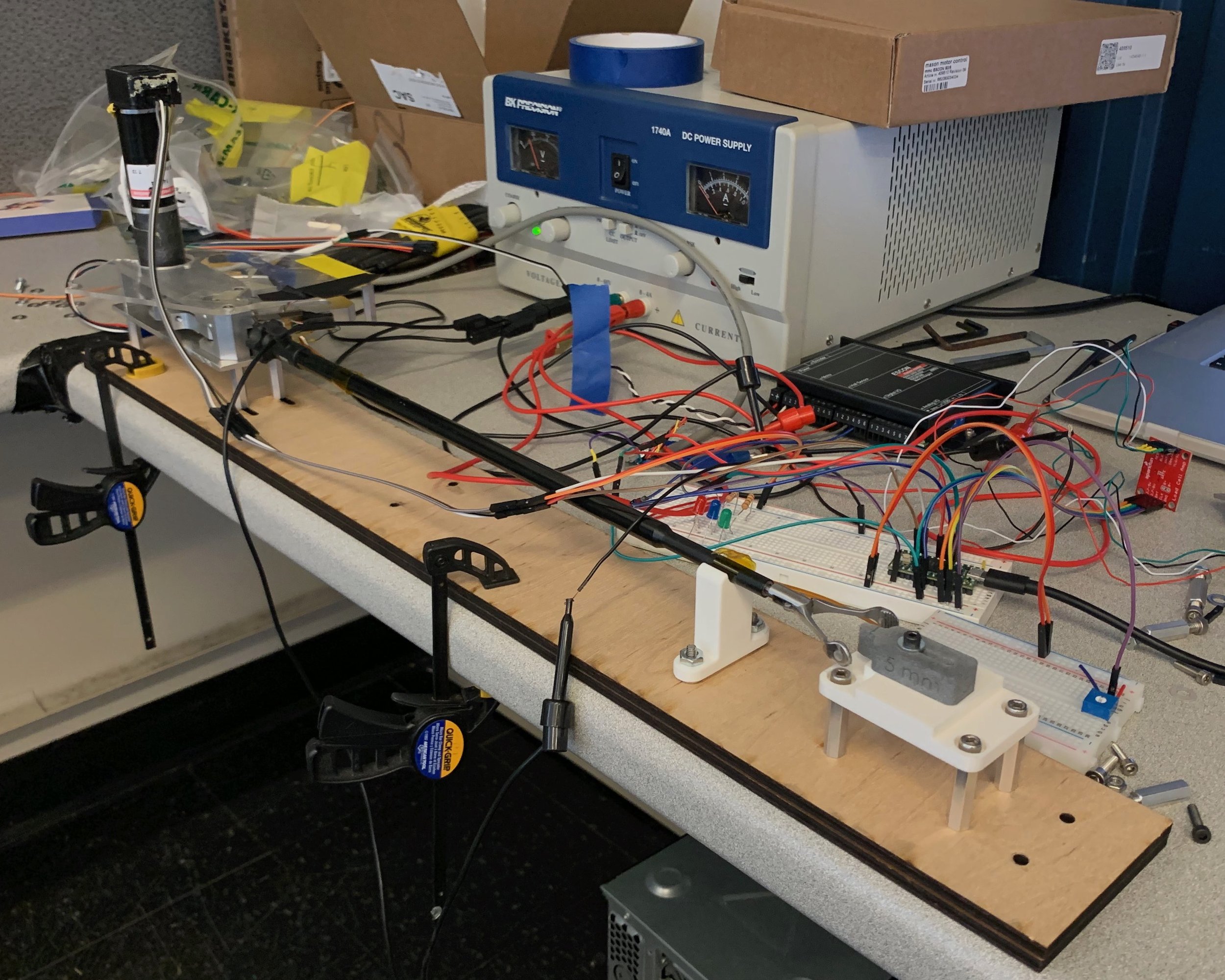

I designed and built a fixture that would allow me to gather the data necessary to find a relationship between the pushrod force and motor position measurements and the jaw force and jaw angle. I then took the data and implemented regressions that allowed me to find the jaw force and position values corresponding to the encoder and pushrod force measurements I had.

Aiding me with this endeavor was Matthew, an undergraduate computer science student. He was competent but lacked experience with mechanical hardware. Working with Matthew was a novel experience for me because until that point, I had usually been the least experienced person working on any major project. Even though Matthew did not formally report to me, I endeavored to provide him with what mentorship I could. The onset of COVID-19, however, ended our working relationship. Gathering data using hardware is difficult to do collaboratively when you cannot be in close proximity. Matthew shifted his attention to another task while I stuck with the original goal of sensor calibration.

This project forced me to become more comfortable working autonomously. Accomplishing anything in a research lab requires motivation. Everybody is working on their own project, and nobody is checking to make sure that you are doing your work. COVID-19 compounded the already inherently individualistic nature of research. Going to the lab required making a reservation to ensure that you would be the only person there. It was harder to get help from other students because everything was remote. Nobody could look over your shoulder as you debugged your code or tried to troubleshoot your electronics.

I also became better at managing my time. During my two years in the BioRobotics lab, I had to balance the short-term needs of my coursework against the long-term demands of my research. It was easy to postpone research in favor of the immediate need to complete whatever assignment was due next. Sometimes focusing on near-term demands was the right decision. Other times, I had to be disciplined enough to chip away at my research project even as other deadlines loomed. It took time, but I was eventually able to learn which items were urgent, which items were important, and which items were both.